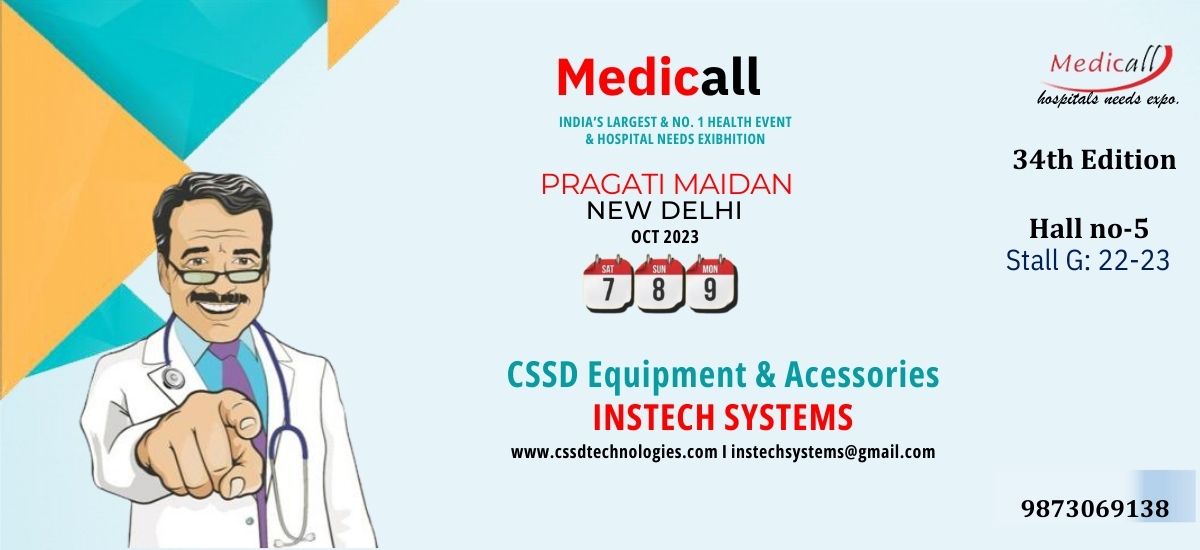

Welcome To "INSTECH SYSTEMS"

INSTECH SYSTEMS started its operations in 1995, under the leadership of B.Tech Graduate from IIT Delhi with rich experience in Industry and intensive interaction with user segments, intending to develop & deliver World-class quality Hospital and Surgical equipment at affordable prices that medical facilities need. An ISO 9001:2000 certified company is a kind of certification that ensures quality (as per International Standards). We are now serving domestic clients & become an exporter to hospitals at the international level. We are reckoned among the most prominent manufacturers and suppliers of CSSD Equipment, CSSD Sterilizer, HPHV Sterilizer, Steam Sterilizer, Sterilizer, ETO Sterilizer, Laboratory Hot Air Oven, Vertical Autoclave, CSSD Furniture, Medical Equipments and Accessories. Our manufacturing range includes CSSD accessories. We are also an importer and trader of high-quality medical and surgical equipment such as CSSD consumables to meet the growing demands in the Indian healthcare industry.

INSTECH is a well-known brand synonymous with the latest technology and high-quality STERILIZATION SYSTEMS (Commonly known as Autoclaves) employing Steam, ETO, HOT DRY AIR, UV Light or Plasma for Hospitals, Pharmaceutical and Research Institutes. We have acquired this recognition over the past 2 decades through consistent efforts.

CSSD Equipments

Steam Sterilizer

We are a Leading Manufacturer of Steam Sterilizer and Hospital Autoclaves and Sterilizers from Ghaziabad, India.

ETO Sterilizer

We are a Leading Manufacturer of ETO Sterilizer and Hospital Autoclaves and Sterilizers from Ghaziabad, India.

Sliding Door Sterilizer

We are a Leading Manufacturer of Sliding Door Sterilizer and Hospital Autoclaves and Sterilizers from Ghaziabad, India.

Washer Disinfector

We are a Leading Manufacturer of Washer Disinfector and Hospital Autoclaves and Sterilizers from Ghaziabad, India

24 years OF EXPERIENCE

Such a long experience! We have a number of satisfied client

CUSTOMIZATION

We make customized lab equipment for specific requirement.

AT YOUR SERVICE

Our specialists advise right equipment for your application.

AFTER SALES

Our technicians install and troubleshoot your equipment.

What is CSSD Equipment? A Comprehensive Guide to Its Role in Healthcare

In the world of healthcare, where patient safety and infection control are paramount, the role of Central Sterile Supply Department (CSSD) equipment cannot be overstated. This equipment is the backbone of medical and surgical facilities, ensuring that all instruments and devices are properly sterilized, cleaned, and prepared for use in patient care.

Future of CSSD Equipment

The future of CSSD equipment lies in further automation, improved sterilization methods, and enhanced monitoring systems. Innovations in sterilization technology, such as vaporized hydrogen peroxide sterilization and robotic automation in instrument handling, are likely to become more prevalent in the coming years. These advancements will continue to improve the efficiency and effectiveness of CSSD processes, ultimately leading to better patient outcomes.