ETO Sterilizer Manufacturer

Instech System is one of the best ETO Sterilizer Manufacturer. We offer a broad range of ETO sterilizers at very affordable prices. ETO Sterilizer is used to kill or eliminate all types of microorganisms like bacteria, viruses, fungi and spores from the surface or from an object. It is generally used in health, medical & laboratory to ensure that the equipment, instruments and surfaces are free from harmful microorganisms.

Full form of ETO Sterilizers:

ETO sterilization stands for Ethylene Oxide sterilization, a low-temperature gaseous process used to sterilize heat-sensitive medical devices and other materials. Ethylene oxide (also known as EO) is widely used to sterilize a variety of healthcare products, such as single-use medical devices. Through the use of a vacuum-based process, EO sterilization can efficiently penetrate surfaces of most medical devices and its lower temperature makes it an ideal process for a wide variety of materials. The ETO gas is used in vacuum processes. The gases must be completely evacuated, as ETO is toxic to humans. To improve production times, the gas exposure time must be minimized.

Features of ETO Sterilizer:

- Effective sterilization with ethylene oxide gas for heat-sensitive materials.

- Precise temperature control to avoid damage.

- Consistent pressure monitoring for efficient gas penetration.

- Programmable cycles for customization based on product needs.

- Eliminates microorganisms (bacteria, viruses, fungi) for sterility.

- Automatic ventilation to safely remove residual gas.

- User-friendly interface for easy monitoring and operation.

- Compliance with regulatory standards (ISO, FDA).

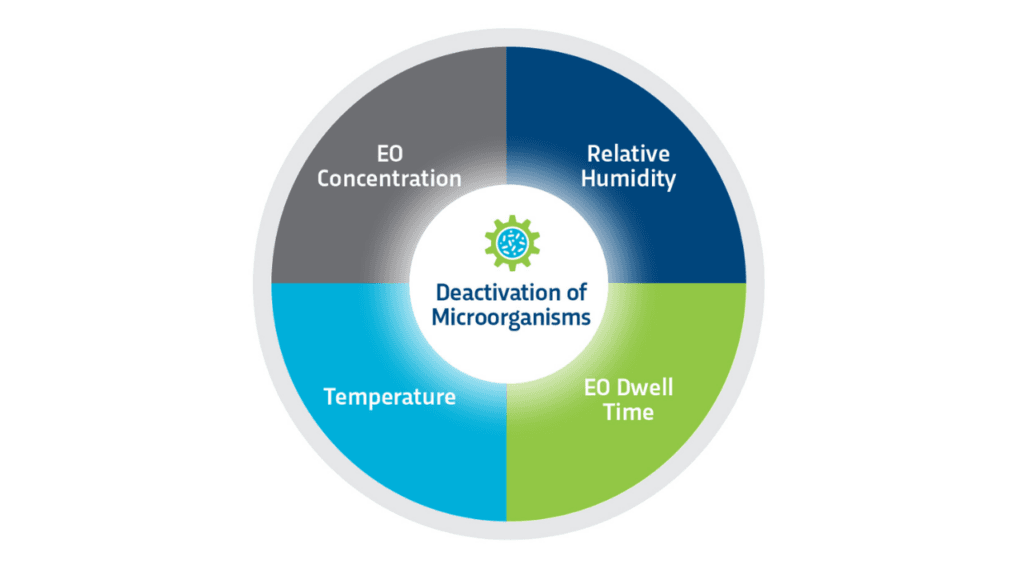

ETO Sterilization Process:

Ethylene oxide (EtO) sterilization is a chemical process that uses ethylene oxide gas to sterilize medical devices and other items. It’s a tightly controlled process that’s critical for preventing infections. The ETO (Ethylene Oxide) sterilization process is a widely used method for sterilizing medical equipment, devices, and other items that cannot withstand heat or moisture. We are manufacturing an extensive List of Industrial Autoclave, ETO Gas Sterilizer, High Pressure Autoclave, Steam Autoclave, Steam Sterilizer etc. In order to manufacture these products, we utilize advanced technology and best quality raw material in Compliance to the set industry Standards.

At Instech System, We have emerged as the best manufacturer and suppliers of ETO Sterilizer. We work with a prime focus on quality, the company has set high standards for manufacturing of ETO Sterilizer in India. With original designs and high quality manufacturing, we have been providing Fully automatic ETO Sterilizers with high tech features for many years. Our ETO Sterilizer chambers are made of finest quality stainless steel.

The products manufactured by us are widely used in various hospitals. Our ETO (Ethylene Oxide Sterilizers) meet our customer’s diverse needs. We manufacture many types of steam sterilizers, like HPHV Steam Sterilizer, Flash Steam Sterilizer and many more pharmaceutical products. If you are looking for an ETO Sterilizer machine, Instech System, the leading ETO Sterilizer manufacturer is the right choice. Feel free to contact us for any information about ETO Sterilization machines.

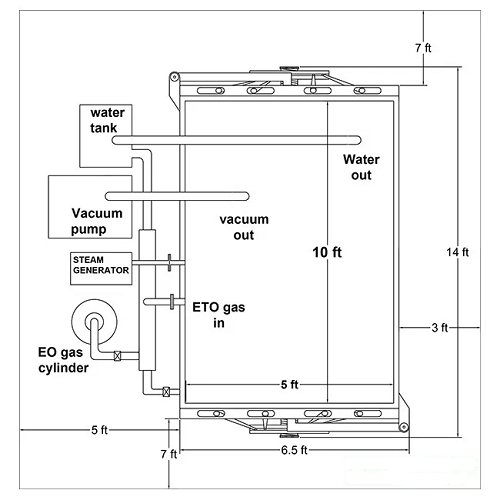

ETO Sterilization Diagram

ETO Sterilizer Machine Specifications

| Application | Hospital |

| Type Of Sterilizer | Ethylene Oxide Sterilizer |

| Material | Stainless Steel |

| Shape | Rectangular |

| Size | 762 X 457 X 457 mm |

| Brand | Instech Systems |

| Liter Capacity | 150 L |

| Volumetric Capacity | 5.62 FT |

Our Products

What is an ETO sterilizer?

An ETO sterilizer, or ethylene oxide sterilizer, is a device used to sterilize heat-sensitive equipment, instruments, and materials by exposing them to ethylene oxide gas. ETO is an effective method for killing bacteria, viruses, spores, and other microorganisms.

Why is ETO sterilization used?

ETO sterilization is preferred for items that are sensitive to high temperatures, moisture, or radiation. It is commonly used in healthcare settings to sterilize items like surgical instruments, electronic components, and certain plastics.

How does ETO sterilization work?

ETO sterilization involves exposing items to a controlled environment of ethylene oxide gas at a specified temperature, humidity, and pressure for a specific duration. The gas penetrates materials, destroying microorganisms’ DNA and preventing their reproduction.

What are the advantages of ETO sterilization?

ETO sterilization is effective at low temperatures, making it suitable for heat-sensitive items. It is also known for its ability to penetrate various materials and is compatible with a wide range of products.

Are there alternative sterilization methods to ETO sterilization?

Yes, alternative methods include steam sterilization, hydrogen peroxide vapor sterilization, and radiation sterilization. The choice of method depends on the items being sterilized and their compatibility with the process.